You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barrel installation question

- Thread starter 65shooter

- Start date

mwezell

Mike Ezell

Y

Chambering a bbl is a pretty simple machining operation but knowing the whys and what fors, like this example, are what separates a gunsmith from a machinist, in this regard.

Yes, but it should be added that this area is very critical as well, in regard to how much unsupported case protrudes from the chamber. Most action designs don't allow for an indiscriminate amount of chamfer, at all. In fact, most don't allow for very much chamfer and still be safe. Coned bolts are a fix for what the op is talking about and are designed the eliminate the flat surface at the breech end of the bbl. Even they only allow for a relatively small chamfer. On these, I break that edge with sandpaper only. It's all ya need to do. Bottom line is, don't get carried away here. They're like this for very good reason.It's absolutely a thing. Depending on the action and it's intended use, a chamfer is requisite. The degree of chamfer depends on whether the barrel will be used for a single shot or magazine fed, but there should always be something other than a sharp edge.

GsT

Chambering a bbl is a pretty simple machining operation but knowing the whys and what fors, like this example, are what separates a gunsmith from a machinist, in this regard.

Last edited:

I ask because there's a little space where a loaded cartridge can sit, when I push the bolt forward that makes the tip of the bullet smash into that 'face' if you will of the barrel. Not sure how a coned bolt would help me. And there's no feel lips per se because it's a blind magazine.

mwezell

Mike Ezell

What action are you working with?I ask because there's a little space where a loaded cartridge can sit, when I push the bolt forward that makes the tip of the bullet smash into that 'face' if you will of the barrel. Not sure how a coned bolt would help me. And there's no feel lips per se because it's a blind magazine.

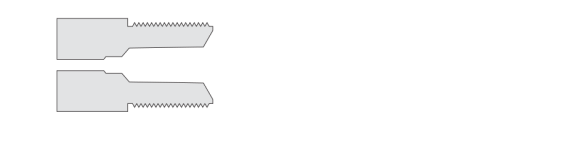

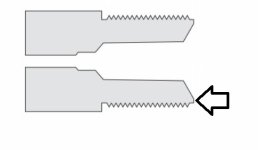

Here's a coned breech

Here's a Remington style..

Last edited:

mwezell

Mike Ezell

I'm confused, as usual. A coned breech like the one pictured above doesn't have any flat area for the bullet to "smash" into. That's why they exist. And, it's possible that your Remington was converted to a coned bolt/breech but they didn't come that way. A pic might help.Tuned 700. Mine looks like the 'coned breach'.

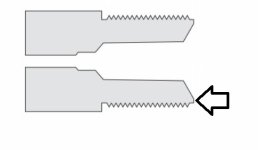

I tried to take pictures but it just doesn't show enough. Here's what I'm working with. See the flat that my arrow's pointing to? I have that flat, but mine's little wider there than the ratio of flat to chamfer shown in your original artwork. My rounds dont jam up in there often but they do smack there sometimes.

mwezell

Mike Ezell

Can't say, because I've never seen what you describe, in 30 years. Anything's possible when you toss a round on the loading ramp and immediately close the bolt though. But yes, that's exactly why coned breeches exist. Tal to your gunsmith and let him know your issue. He can make that are damn near NO transition. To the point that I see it as rare, that it could even "bounce" there. Geometry puts the bullet tip above a large area there unless it's still moving while you close the bolt. The 30's are a tad bit worse, so it's not like I haven't seen this but it's still rare....or you're really fast. The simple answer may be to start the tip of the bullet into the chamber when loading. Sounds harder than it is. I've shot a 30 Major (Grendel) for several years, over several different actions, including drop ports. The smaller case diameter can only make it worse, along with a heavier 30 cal bullet. No problems that I can remember.I tried to take pictures but it just doesn't show enough. Here's what I'm working with. See the flat that my arrow's pointing to? I have that flat, but mine's little wider there than the ratio of flat to chamfer shown in your original artwork. My rounds dont jam up in there often but they do smack there sometimes.

View attachment 27015

Last edited:

What does your bolt nose look like? That's more than a chamfer on the conical breech, and it mates with a 'coned' bolt, not your typical '700 bolt.

GsT

Oh I see what you're saying; that this is only for a coned bolt. No, I have a standard issue 700 bolt-no coning. I'll try to take some pictures. Gotta get creative.

I load kind of quick, but I wouldn't say it's fast at all. Shooting 6.5 creed.Can't say, because I've never seen what you describe, in 30 years. Anything's possible when you toss a round on the loading ramp and immediately close the bolt though. But yes, that's exactly why coned breeches exist. Tal to your gunsmith and let him know your issue. He can make that are damn near NO transition. To the point that I see it as rare, that it could even "bounce" there. Geometry puts the bullet tip above a large area there unless it's still moving while you close the bolt. The 30's are a tad bit worse, so it's not like I haven't seen this but it's still rare....or you're really fast. The simple answer may be to start the tip of the bullet into the chamber when loading. Sounds harder than it is. I've shot a 30 Major (Grendel) for several years, over several different actions, including drop ports. The smaller case diameter can only make it worse, along with a heavier 30 cal bullet. No problems that I can remember.

GeneT

Active member

Does this problem occur only when feeding from the magazine, or when single-loading as well?

Reliable magazine feeding can be tough. Probably the easiest thing to do is play around with your OAL. Of course this isn't ideal, since you'd like to make those adjustments based on performance, but since you're magazine feeding you're already limited to "max magazine OAL", so the compromise is already present to some degree.

A removable magazine bottom metal might be an expensive solution, particularly one that uses a magazine that feeds from a single column (the lower part of the magazine can be staggered). That style reaches a bit closer to the center of the action, the round moves straight up (rather than in from alternating sides) and may also help.

GsT

Reliable magazine feeding can be tough. Probably the easiest thing to do is play around with your OAL. Of course this isn't ideal, since you'd like to make those adjustments based on performance, but since you're magazine feeding you're already limited to "max magazine OAL", so the compromise is already present to some degree.

A removable magazine bottom metal might be an expensive solution, particularly one that uses a magazine that feeds from a single column (the lower part of the magazine can be staggered). That style reaches a bit closer to the center of the action, the round moves straight up (rather than in from alternating sides) and may also help.

GsT

mwezell

Mike Ezell

Best thing is probably to train yourself to barely start the round into the chamber when you lay it on the loading ramp. It's easy but you just have to teach yourself to give it that little nudge forward every time. Done right, it shouldn't slow you down at all and will be second nature in no time at all.I load kind of quick, but I wouldn't say it's fast at all. Shooting 6.5 creed.

It's the traditional Remington bdl blind magazine componentry. At this time, my loads haven't reached the oal that would prohibit it from loading into that mag yet. I have another round of load development coming up for it so we shall see if I have to go out longer than mag length oal.

mwezell

Mike Ezell

That may be part of your problem if you're trying to feed from a mag with a coned bolt. It typically doesn't work well. That's why I can't name a single repeater with a coned bolt, minus crf winchesters, I guess. But crf is the key there.It's the traditional Remington bdl blind magazine componentry. At this time, my loads haven't reached the oal that would prohibit it from loading into that mag yet. I have another round of load development coming up for it so we shall see if I have to go out longer than mag length oal.

A pic of your bolt would still be nice to see.